Industrial

Industrial applications are often complex in nature as they typically require advanced hardware and expertise. Whether measuring vibration of pipes or deformation of wind turbines, we have you covered. Continued advancements in machine vision cameras and advanced software have allowed digital image correlation to become the go-to measurement technology for more industrial applications. Applying a speckle pattern to large-scale objects can be a challenge, but typically the benefit of the measurement results obtained far outweigh the time it takes to apply the pattern. However, if only displacements at discrete points are needed, ellipse or quadrant markers may be substituted for a speckle pattern to track these points using VIC-3D’s marker tracking interface. Furthermore, with VIC-3D’s intelligent large-scale stereo calibration feature, a calibration target no larger than 90 cm x 60 cm is used to calibrate the stereo system with a field of view of virtually any size. For example, this setup would be used to calibrate a VIC-3D system in order to measure the blade deflections of a ~100 m diameter wind turbine.

Application Examples

Adhesion Energy of Graphene on Nickel Substrates

In this study performed at the University of South Carolina, for the first time, the VIC-3D system was used on a novel 3D blister test to characterize the interfacial interaction between graphene (G) on nickel (Ni) and copper (Cu) substrates. This powerful research demonstrates how DIC can be used to better understand the properties of graphene and how the material may be used in high-powered capacitors and batteries in the future.

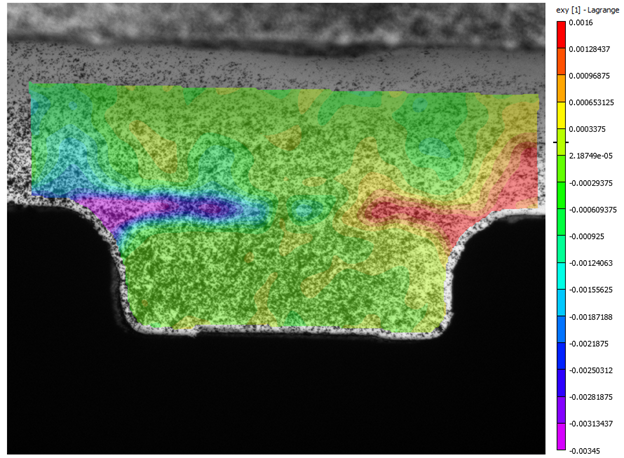

DIC for Understanding Multistage Incremental Sheet Forming

Incremental Sheet Forming (ISF) is a manufacturing method whereby a 3D geometry is created by progressively deforming a metal sheet with a single-point tool. ISF has many advantages for rapid prototyping and is a more cost-effective alternative to die-forming. The geometric accuracy and thickness distributions are important to ensure process efficiency, which is examined using the VIC-3D system.

Stereo Microscope and Capacitor Chip Assembly

The VIC-3D Stereo Microscope system enables local analysis within very small elements. Small ceramic capacitor chips are too small for traditional measurement methods or standard DIC systems to provide enough resolution to obtain local strain distribution of the capacitor chip, board, and the soldering area in between the board and chip. Complex distortions are removed using Correlated Solutions' patented distortion correction module.