Civil

Large infrastructure components, such as bridges, roofs, transportation tunnels, power plants, and dams, require reliable and robust monitoring methods to economically evaluate current conditions and schedule maintenance to ensure structural safety. Historically, limited discrete measurements were acquired using legacy systems such as strain gages, extensometers, or direct visual inspection. Today, a modern, robust full-field optical monitoring technique, stereo digital image correlation (VIC-3D), has become the measurement method of choice in many infrastructure applications. Developed and converted into an industry-ready platform by Correlated Solutions Incorporated scientists and engineers, stereo DIC has been shown in both laboratory and field environments to be capable of acquiring accurate, whole-field measurements on large structures. The industry-leading DIC systems from Correlated Solutions not only provide a dense set of data where legacy technologies were used previously but also provide data everywhere on the structure so that the entire field of view can be inspected to identify damaged areas (e.g. cracks, weld separation) where legacy systems were not located.

Today, stereo DIC systems from Correlated Solutions have been deployed around the world in a wide variety of civilian infrastructure applications. Here are just a few examples.

Speckles for Safety

The National Institute of Standards and Technology (NIST) and the Federal Highway Administration (FHWA) have used Correlated Solutions digital image correlation technology to better understand how stress and strain could lead to their bridge failure. This short video explains the process of speckling and testing the metal connections that are vital to modern highway bridges.

Application Examples

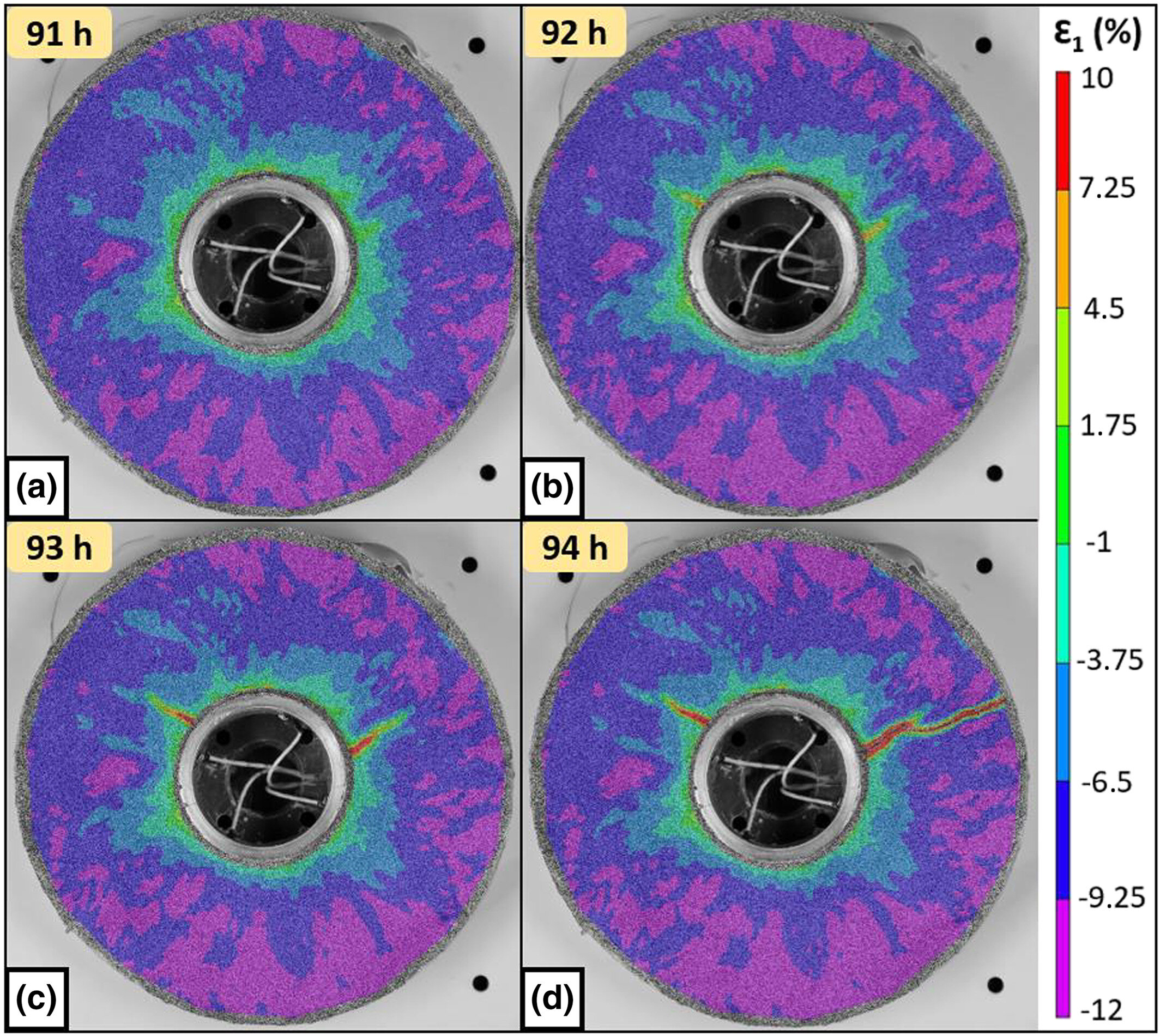

Soil Cracking Testing with Digital Image Correlation

Aiming to understand the shrinkage mechanism and conditions that lead to the appearance of drying cracks, digital image correlation was used to investigate fine soils' shrinkage and cracking. In this example, the VIC-3D system was the only option for identifying these cracks and measuring the surrounding strains due to the non-contact nature of the technology.

Large-scale DIC with VIC-3D for Bridge Inspection

Measuring bridge deformation is vital to ensure structural integrity and safety, and it is time-consuming and non-quantitative to visually inspect bridge supports. Scientists at UVA utilized VIC-3D to measure full-field strain distribution and buckling of a steel plate under a compressive load of 8 Kips (800 lbs force).

Large-Scale Concrete Strength Test

Researchers used three VIC-3D systems with high-resolution cameras to capture images of 16 ft by 4 ft concrete beams. They chose the VIC-3D Multi-System because of its full-field ability to measure high-spatial resolution strains over the entire surface of a large test subject and combine data from all stereo systems into a common coordinate system.