Primary Systems

The VIC-2D system is a turnkey solution that utilizes optimized correlation algorithms to provide full-field two-dimensional displacement and strain data for mechanical testing on planar specimens. In-plane displacements and strains are measured at every pixel subset within the area of interest, and full-field contour plots are displayed at every time step.

The VIC-3D 9 system is an industry-leading measurement solution for full-field, three-dimensional shape, displacement, and strain. Using this method, 3D displacements and strains are available at every point on the specimen’s surface. All systems are customized to your needs and are available for a wide range of size scales for quasi-static and dynamic events.

The VIC-EDU system is a low-cost solution developed for academic institutions to assist in teaching the digital image correlation technique to undergraduate and graduate students. The VIC-EDU system utilizes the same accurate DIC algorithms found in the powerful VIC-3D software, while allowing users to acquire data quickly and easily.

VIC-Volume is a digital volume correlation (DVC) software that utilizes quantitative image analysis for measuring the internal deformation of a volume from image slices acquired via an X-Ray or CT scanner. The theory is similar to 2D and 3D DIC analysis, except the z dimension (through the material) is added allowing for full characterization of the material.

Specialized Systems

The VIC-3D High-Speed (HS) system is a high-speed measurement system for full-field shape, displacements, velocities, strains, and much more. With frame rates from 1,000 to 500,000 Hz systems configurations can be customized to your applications and budget.

The VIC-3D Ultra High-Speed (UHS) system utilizes the fastest cameras (frame rates up to 5 MHz) on the market for ultra high-speed DIC applications, including explosive testing, high-velocity partial acceleration, ceramic fracture research, and more.

The VIC-3D IR system is an integrated non-contact solution for measuring the deformation and temperature of an object simultaneously. Accurate & localized CTE measurements are possible due to a unique calibration procedure that combines the strain and temperature data into one common coordinate system.

The Stereo Microscope system is a highly accurate system for measuring surface shape, deformation, and strain on micro-scale specimens. The accurate measurements are obtained by utilizing a stereo microscope with a specially designed beam splitter and a patented distortion correction algorithm.

The VIC-3D Multi-System is available with up to 16 cameras on one control computer allowing for multi-surface imaging of large or complex geometry specimens. The intelligent analysis software combines all the data into a common coordinate system, even if there is no image overlap or when systems are facing each other.

The Shearography system utilizes a technology called speckle interferometry that uses lasers in combination with a white light camera to measure in-plane and out-of-plane strain and deformation measurements, vibration analysis, and non-destructive testing (NDT). The system can detect sub-surface defects such as impact damage, delamination, or even cracks.

The VIC-3D Quasi-Static system is a common configuration of the VIC-3D system for measuring deformation and strain on specimens under ‘slow’ loading. Whether performing simple tensile tests, compression tests, or applying large loads to structures, this system has the power to deliver accurate results with high spatial resolution.

The 3D-Micro-DIC stereo system is designed specifically for full-field strain and deformation measurements on micro-scale specimens with the highest accuracy and resolution. It also operates as a real-time extensometer for stain control. Interchangeable configurations are available for 0.5X, 1X, and 2X magnifications with 5-megapixel cameras and 75Hz.

All VIC-3D systems include these powerful features

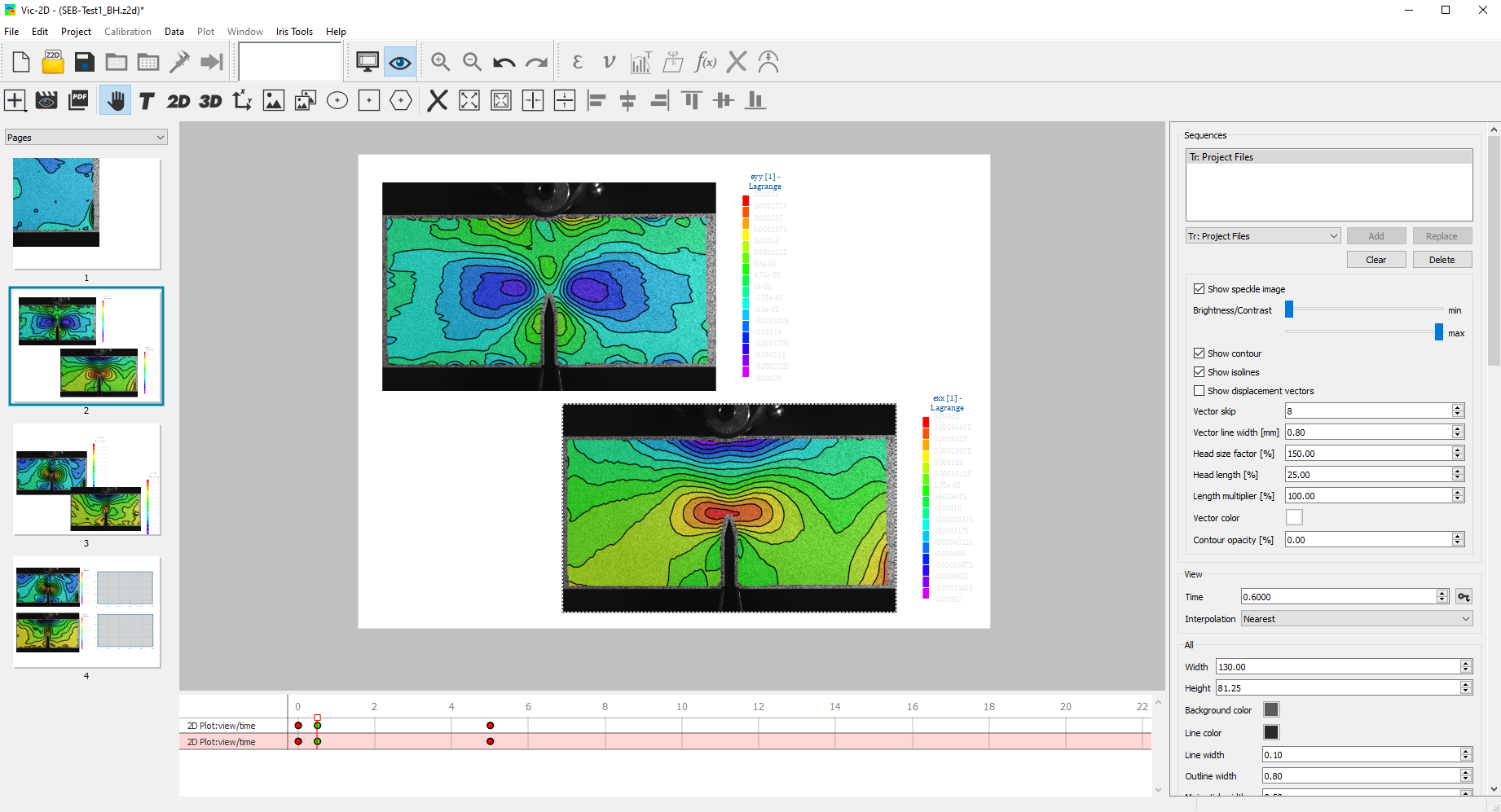

Data Visualization with iris

This new graphics engine brings a host of new functionality all from within the VIC-3D workspace. Iris is a powerful integrated workspace that allows the user to create and share high-resolution presentations efficiently that contain smooth animations. Iris has been designed from the ground up and contains highly anticipated new features, such as FEA importing for validating measurement data.

VIC-Snap

VIC-Snap is a complete image acquisition software for all supported cameras. Designed specifically for VIC-2D and VIC-3D, this software allows the user to directly import images into the analysis software with one click. Built-in tools for calibration and image analysis ensure optimized focus, brightness, and pattern quality every time. Analog data is also recorded for easy synchronization of external data.

Discrete Marker Tracking

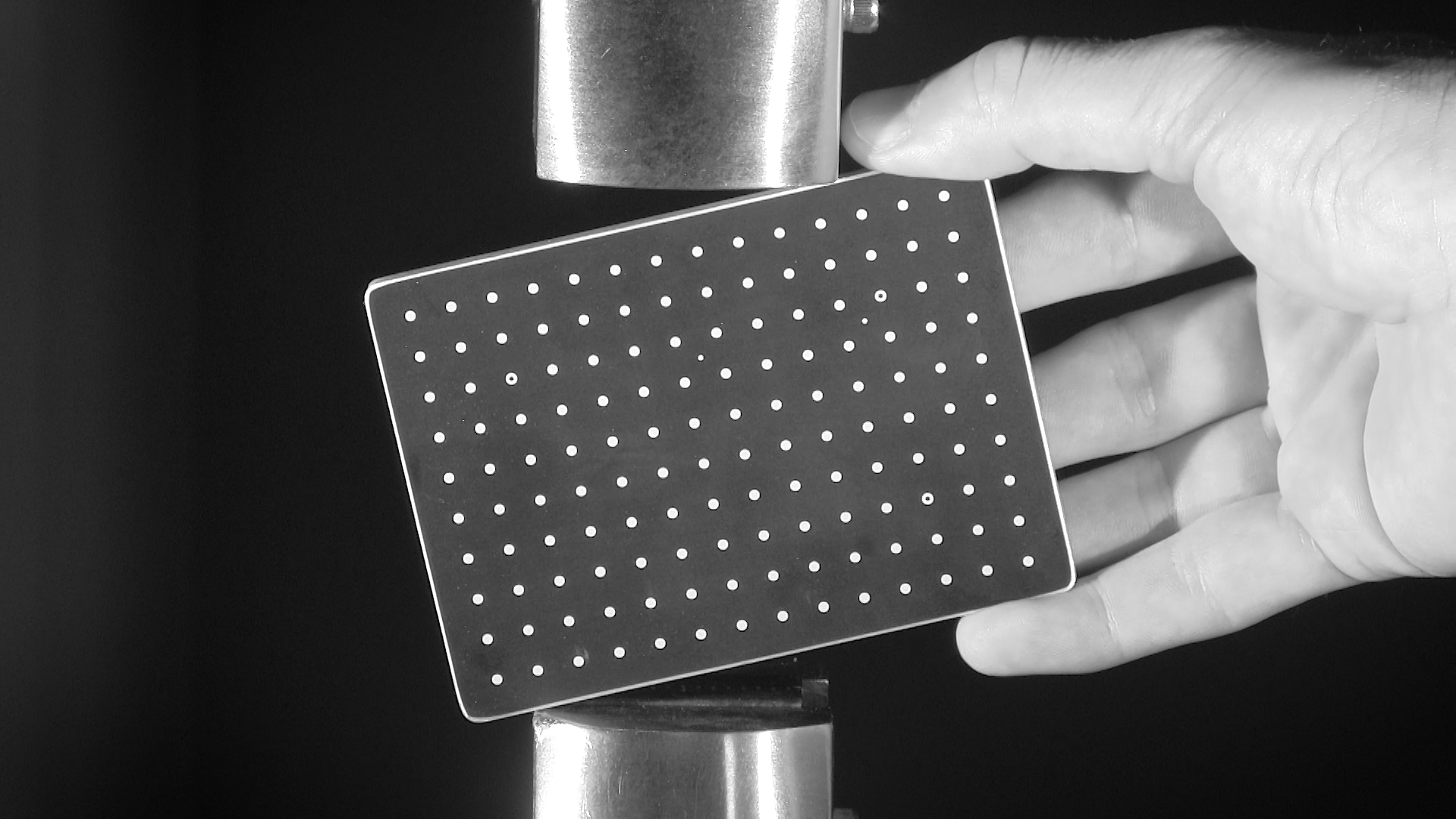

Discrete Marker Tracking is included in VIC-3D. DMT is the ability to track circular or quadrant markers that are commonly used in crash testing and civil engineering. Markers can be printed or painted directly onto the surface of the object and the centers are tracked in 3D. This feature saves considerable time compared to full-field speckling when displacements at discrete locations are all that is desired.

Modules

Fatigue/Vibration

The VIC-3D Fatigue & Vibration module allows low-speed cameras to capture displacement and strain measurements during periodic, high-speed events. VIC-Snap allows the user to accurately trigger the low-speed cameras at peaks, valleys, or phase intervals.

VIC Gauge (real-time)

VIC-Gauge uses optimized 2D and 3D correlation algorithms to provide real-time displacement and strain data at user-defined locations. Think of this tool as a set of virtual strain gauges and/or extensometers that can be outputted live for real-time strain control.

Full-Field Real Time

The VIC-3D Real-Time processing module allows thousands of full-field data points to be displayed live while a test is running. This provides users with the information needed to make critical adjustments during the test, ensuring the loading is applied as expected.