Non-Contact Full-Field Thermal and Strain Measurement System

The VIC-3D IR system is an integrated non-contact solution for measuring the deformation and temperature of an object simultaneously. Accurate & localized CTE measurements are possible due to a unique calibration procedure that combines the strain and temperature data into one common coordinate system. This fully integrated imaging system accurately calibrates the two imaging systems so temperature and strain data are accurately displayed in a common coordinate system. The system is turnkey and ready to use right out of the box and includes onsite installation, and one year of unlimited technical support with every purchase. The thermal imaging capability may also be added to any existing VIC-3D system for increased functionality. For more details about this product, and to see an application example, please download our VIC-3D IR system brochure.

Technology Overview

VIC-3D System with IR Cut Filters

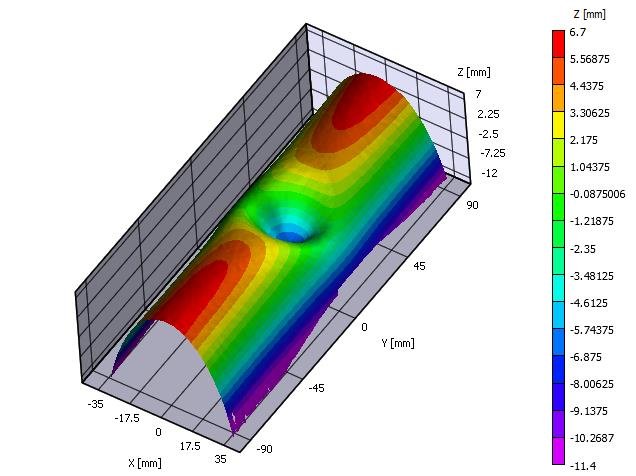

The VIC-3D IR system integrates an infrared (IR) camera with the white light DIC cameras enabling temperature data to be accurately analyzed alongside full-field strain data. The system works by first synchronizing images from the IR camera with images from the stereo DIC system, and then calibrating all three cameras so that the thermal and strain data are in a common coordinate system.

This calibration procedure has been streamlined using the VIC-Snap IR software, which allows the user to capture synchronized single images for calibration, and multiple images at a constant rate for quasi-static testing. The result is an easy-to-use turn-key thermal imaging system that utilizes digital image correlation technology to accurately measure temperature and strain concurrently without any contact with the sample. Thermal and strain data can be viewed, analyzed, and extracted over the entire field or at precise locations.

Features

Images from VIC-3D showing speckle image quality of the 800C heated specimen vs. the room temperature image

Temperatures up to 2,000C

Synchronized IR and DIC images

User-friendly setup and calibration

Uniquely designed IR calibration targets

Analog data synchronization

Extract points, regions, or nodes locations for FEA validation

Accurately measure deformation and thermal data concurrently

Remotely view and acquire images using the Vic-Snap remote

Measure 3D full-field displacements and strains

All the features for the VIC-3D system included

Thermal DIC Applications

Whether working with metals, composites, ceramics, or biological specimens, thermal testing is a growing field for many researchers and engineers in academia and commercial industries. Temperatures ranging from -40C to 2,000C can be measured with great accuracy. Some examples of high-heat applications include (but are not limited to) the following:

Military – Vehicles, UAVs, armor, firearms, etc.

Automotive – Exhaust manifolds, turbochargers, superchargers, engine components, brake systems, heat exchangers, etc.

Aerospace – Engine components, fuselages, wing sections, spacecraft re-entry, etc.

Civil – Walls, buildings, concrete structures, steel beams, etc.

Experimental – Metal alloys, composites, polymers, concrete, etc.

IR and DIC data combining is useful any time thermal characteristics are part of a mechanical test. Some other application examples are listed below:

Heat-induced softening of steel

Blistering and delamination in composites

Strain-induced heating in polymers

Correlating heat transfer and strain distribution during bonding/debonding

Matrix and fiber or particulate composite testing

There are many other possible thermal applications where this measurement system may be used. If there is a need to measure full-field displacements and strains concurrently with temperature data, then this is the right system for you.