Non-Contact Full-Field Dynamic Strain Measurement System

(Up to 5,000,000 frames per second)

The VIC-3D Ultra High-Speed (UHS) digital image correlation system utilizes the fastest cameras on the market for ultra-high-speed DIC applications requiring frame rates up to 5 MHz. Examples of applications in which the UHS system has been deployed include explosive testing, high-velocity partial acceleration, and ceramic fracture research. The system is completely supported by our technical staff and is installed by experienced engineers.

Fully Integrated Ultra-High-Speed Camera Control

When acquiring images by conventional means with Ultra-High-Speed (UHS) cameras for 3D DIC, the manufacturer’s acquisition software is not designed to acquire single pairs of synchronized images with ease, which is a requirement for 3D calibration. With the development of VIC-Snap UHS, the user has the ability to take single image sequences for calibration and a series of images for testing. Having the capacity to perform both types of acquisition for multiple cameras at once can save hours of time during the calibration phase of DIC testing and streamlines the process.

VIC-Snap UHS Image Acquisition Software

With the development of VIC-Snap UHS, the user has the ability to easily acquire image sequences for calibration and testing, while synchronizing external analog data with the included data acquisition system. Having the capacity to perform both types of acquisition saves dozens of lab hours during the set up and data collection.

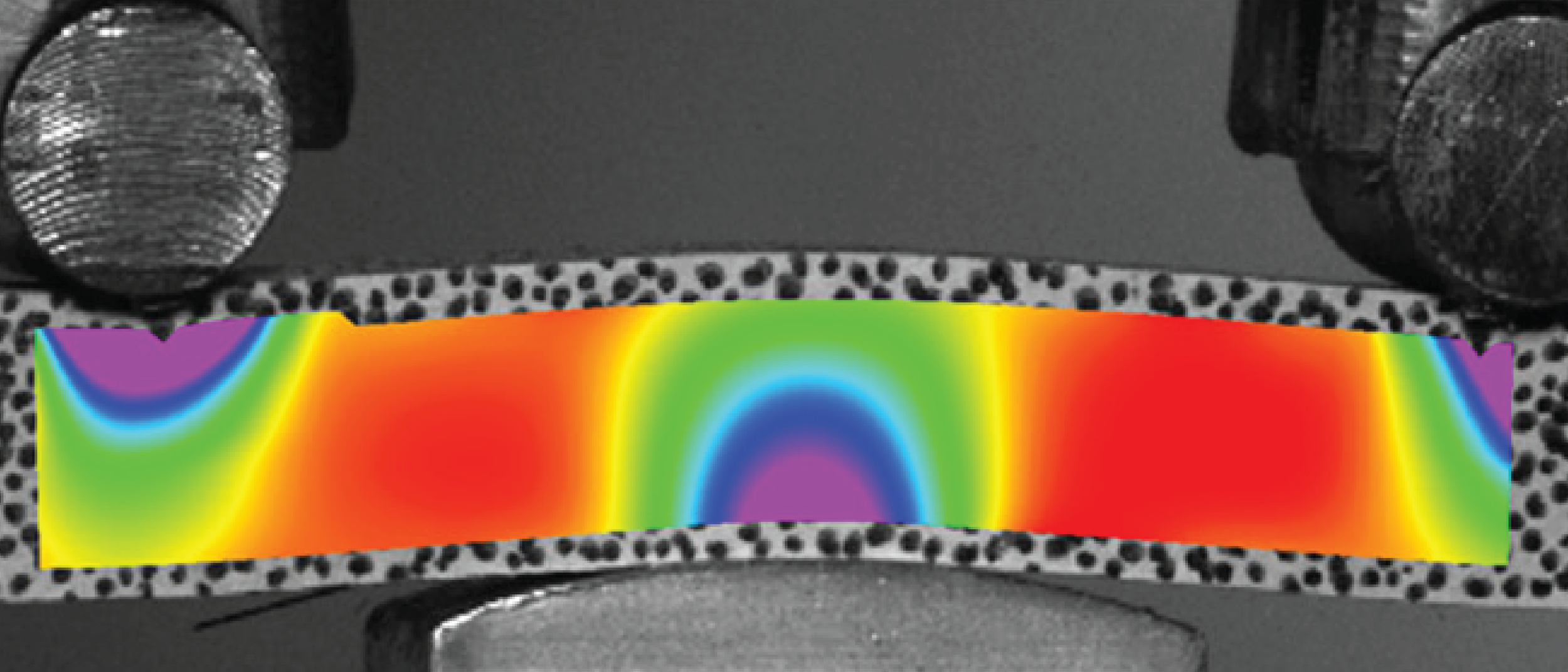

“The purpose of the impact test is to determine how the dynamic characteristics of the material properties differ from the static properties. The importance of using the VIC-3D system is the fact that there are steep strain gradients on the face of the specimen. We would never get the strain information we need using a strain gauge.”

-Brian Shonkwiler, University of Texas Arlington

Application Example

Ultra-High-Speed, Super Dynamic Bend Test

Professors at the University of Texas Arlington Mechanical and Aerospace Engineering department are utilizing the VIC-3D UHS system to measure dynamic properties of a glass/epoxy material. The purpose of this Short Beam Shear test is to measure multiple material properties such as shear & axial modulus, and shear strength.