Non-Contact Full-Field ODS & Strain Measurement System

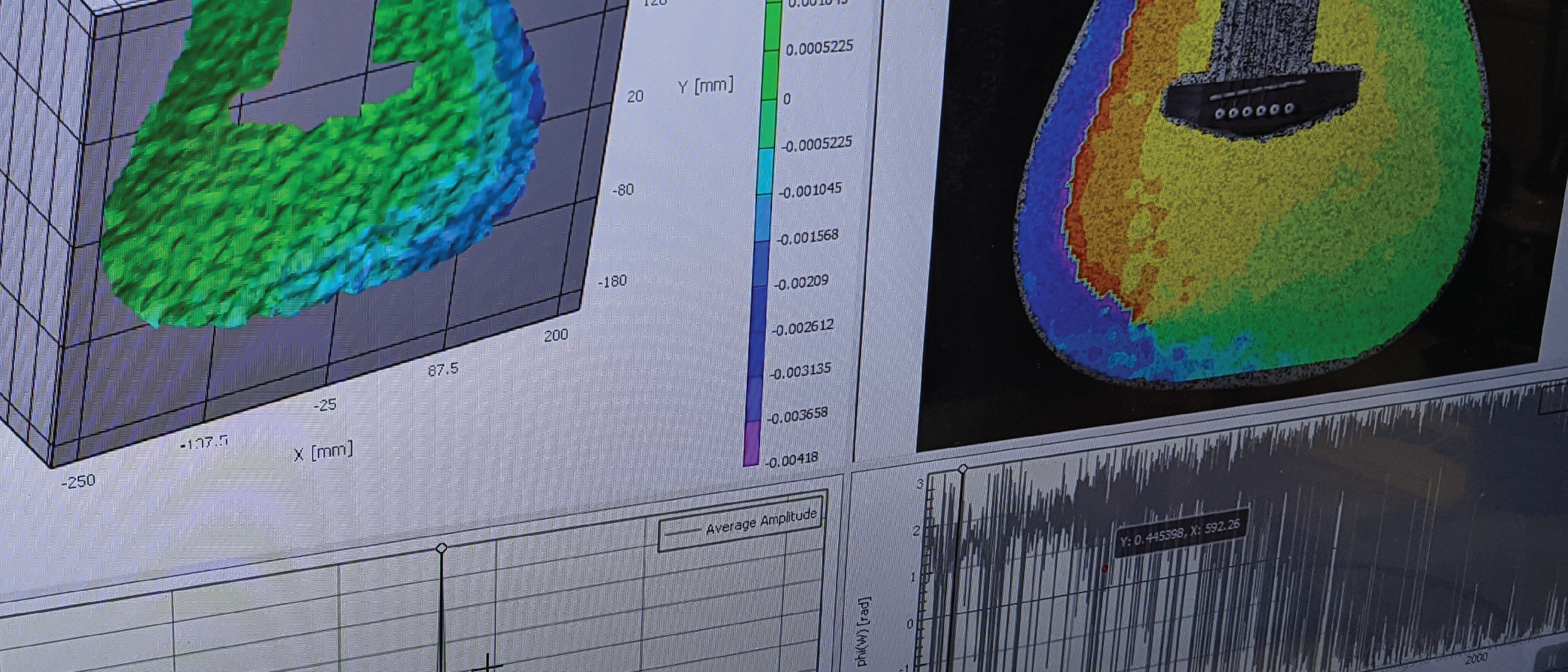

The VIC-3D Vibration Analysis (FFT) system by Correlated Solutions enables full-field 3D viewing, measurement, and analysis of full-field operational deflection shapes (ODS) from an impact, a driving frequency, or from a transient event. ODSs in the frequency domain can easily be identified, visualized, and measured with levels of accuracy in the nanometer range. Three-dimensional displacements, strains, velocities, and accelerations are all computed for thousands of data points in the frequency domain. ODS frequencies at just under half of the acquisition rate of the cameras are measured. Data can easily be exported in ‘universal file format’ for further analysis.

An example of the system’s results can be seen in the image to the right. A thin 8″ x 10″ aluminum plate suspended was excited from behind with a small hammer. The impact produced the shapes featured to the right.

This short video - produced in 4K entirely with the iris visualization engine that comes standard with the VIC-3D HS FFT digital image correlation software - features the results of a recent test conducted with Phantom High-Speed T3610 cameras to find the operational deflection shapes (ODS) which occur after excitation of a tuning fork.

System Features

View, compare, animate, graph, extract, and export FFT data for easy FEA comparison

Quickly identify frequency peaks and animate full-field x,y, and z ODSs

Measure 3D full-field, high-frequency operational deflection shapes (ODS) with nanometer resolution

Large dynamic range

Measure full-field strain, deformation, and shape variables

Quick and easy to set up with a short acquisition time (<1s)

User-friendly commercial software with powerful features

Cost-effective solution to other non-contacting systems such as LDVs

Logarithmic scaling, and many analysis options for windowing and filtering

Other applications the VIC-3D Vibration Analysis (FFT) System maybe use used for include, but are not limited to, the following:

Explosive Testing

Door Slams

Run-ups/Run-downs

Shake Testing

Drop Testing

VIC-3D Vibration Analysis (FFT) System vs. Accelerometers

Non-contact measurements – Because the VIC-3D FFT System uses a non-contacting measurement technique, drawbacks associated with conventional contacting sensors pose no problems. No careful consideration needs to be given for debonding, sensor damage (especially due to overheating or impulse loading), mass loading, or advanced cable management.

Full-field data – Point selection or applying markers or reflectors is not necessary. Since the measurement covers the entire image area, unknown nodes are easily identified and displayed during the analysis. No pretesting is necessary to ensure reliable results.

3D – Since the VIC-3D Vibration Analysis (FFT) system always measures in all three axes, orienting multiple single-axis accelerometers or using pricey bi-axial or tri-axial accelerometers are no longer required.

Integrated strain and displacement data – Full-field shape, displacements, and strain values vs. time are automatically computed during the DIC analysis, so raw data is always present for multiple and complex frequency analyses.

With the VIC-3D Vibration Analysis (FFT) system, there are no adhesives, wires, signal analyzers, power amplifiers, or load cells necessary for detailed ODS results. Obtaining data for a tiny, complex structure or a very large one is faster and easier than changing a pair of lenses.

Vs. Single-point laser vibrometers

3D Results – Since the VIC-3D Vibration Analysis (FFT) system always measures in all three axes, 3D results are obtained with each test.

Simple procedures – Very large structures can be measured in only a single transient test. The cameras do not need to be moved or repositioned at all to acquire additional data from the specimen.

Faster acquisition – With the VIC-3D Vibration Analysis (FFT) system, the amplitude does not affect acquisition time. Even on very large structures with very large amplitudes, full-field image acquisition time requires only seconds.

Integrated strain and displacement data – Full-field strain, deformation, and shape variables are automatically produced along with frequency and amplitude data.

Single-point laser vibrometers are not as robust as the VIC-3D Vibration Analysis (FFT) system. Full-field 3D data can be acquired very quickly and with very little setup and testing time.

Vs. Scanning laser vibrometers

Smaller equipment– The cameras used for the VIC-3D Vibration Analysis (FFT) system fit on a single tripod, which makes the system quite portable. Moving your 3D vibration measurement system from lab to lab or out to the field for testing has never been easier.

Less Expensive – A VIC-3D Vibration Analysis (FFT) system will be much lower in cost than a comparable 3D laser scanning vibrometer system.

Faster acquisition– With the VIC-3D Vibration Analysis (FFT) system, the amplitude does not affect acquisition time. Even on very large structures with very large amplitudes, full-field data acquisition time requires only seconds.

Integrated strain and displacement data– Full-field strain, deformation, and shape variables are automatically produced along with frequency and amplitude data.

Scanning laser vibrometers provide measurements in 3D, but are quite bulky and expensive. When compared to acquiring measurements with DIC, you can look forward to more compact equipment at a smaller price.