Applications

The DIC systems from Correlated Solutions excel in every imaginable application.

Our digital image correlation (DIC) systems have been implemented successfully in a wide range of applications from automotive to biological, and size scales from microscopy to large structures. All DIC systems are sold as turnkey solutions, which are customized to your measurement needs. Our systems include all hardware, software, technical support, onsite installation, and equipment training. We are dedicated to providing our customers with quality technical support and free software upgrades for one year after the date you receive your system.

Investigating the Strain and Degradation Parameters of Rapidly Discharging Lithium-ion Batteries using 3D Digital Image Correlation

Correlated Solutions recently assisted in an important research project in the College of Engineering and Computing at the University of South Carolina with members of Dr. Austin Downey’s research group who are investigating the degradation parameters of rapidly discharging Lithium-ion batteries in the ARTS lab (Adaptive Real-Time Systems). In some cases – especially in defense and aerospace applications – it is necessary to push battery performance to extreme limits. Dr. Downey’s team, working with support from the NSF and Airforce Research Laboratory are using a NHR 9200 Battery Test System to investigate the material characteristics of an 18650 2500mAh 20A battery as it rapidly discharges.

In this test, the focus is on Current Interrupt Devices (CID). CIDs play a critical role in ensuring safety in high-performance battery applications by interrupting current flow when it exceeds a predetermined safe limit. This prevents battery cells from overheating, which can lead to damage, fire, or even explosion. In high-performance batteries that are designed to deliver large amounts of current very quickly, this protection is essential to prevent catastrophic failure.

DIC for Rail Neutral Temperature & Stress Measurements

The proposed method is based on measurements of nonuniform deformations of the rail under thermal loading, as observed in computer simulations and laboratory investigations. The implementation uses thermal imaging and three-dimensional stereo-digital image correlation technology to acquire full-field deformations.

Thermomechanical Response Measurement on Composites Using Infrared Thermography and DIC

Understanding thermo-mechanical behavior of material can be a vital component when designing vehicles and structures that may become exposed to high temperatures. Virginia Tech’s Extreme Environments, Robotics, and Materials (ExtReMe) Laboratory focuses on the impact of extreme environments on materials. This includes research that is focused on understanding the thermo-mechanical behavior of materials both during and following fires. Experimental investigations are performed to understand the evolution of the material due to elevated temperature.

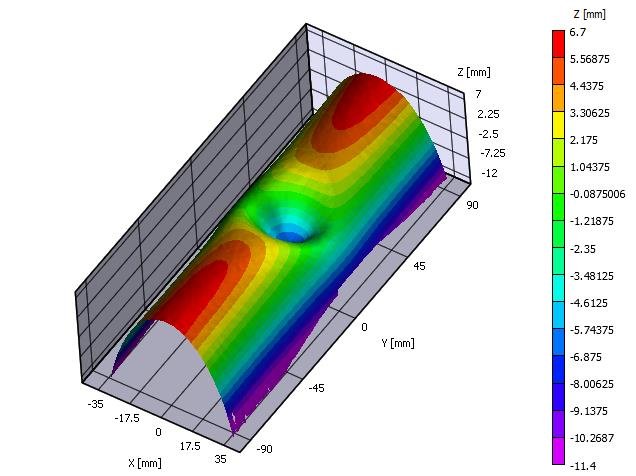

Printed Circuit Board (PCB) Measurement from Thermal Loading

Printed circuit boards (PCBs) have two primary functions: to provide electrical connections between terminals on the board, and to affix electronic components such as resistors, capacitors, and microchips via soldering. PCBs are used in many devices around the world on a day-to-day basis. Their small and lightweight design allows them to be found in nearly every electronic device, such as smart watches, phones & computers, and even digital cameras.