Applications

The DIC systems from Correlated Solutions excel in every imaginable application.

Our digital image correlation (DIC) systems have been implemented successfully in a wide range of applications from automotive to biological, and size scales from microscopy to large structures. All DIC systems are sold as turnkey solutions, which are customized to your measurement needs. Our systems include all hardware, software, technical support, onsite installation, and equipment training. We are dedicated to providing our customers with quality technical support and free software upgrades for one year after the date you receive your system.

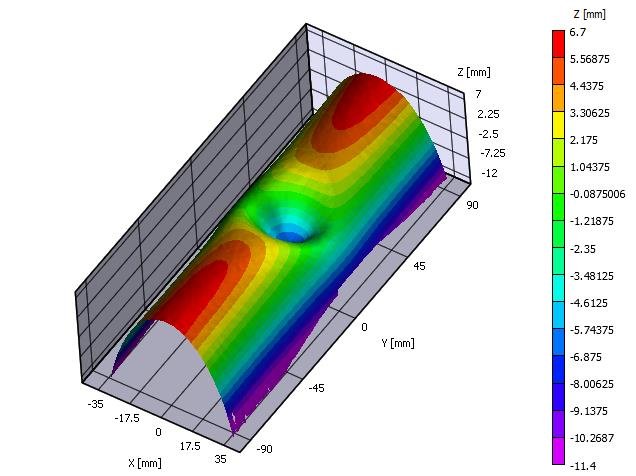

DIC for Rail Neutral Temperature & Stress Measurements

The proposed method is based on measurements of nonuniform deformations of the rail under thermal loading, as observed in computer simulations and laboratory investigations. The implementation uses thermal imaging and three-dimensional stereo-digital image correlation technology to acquire full-field deformations.

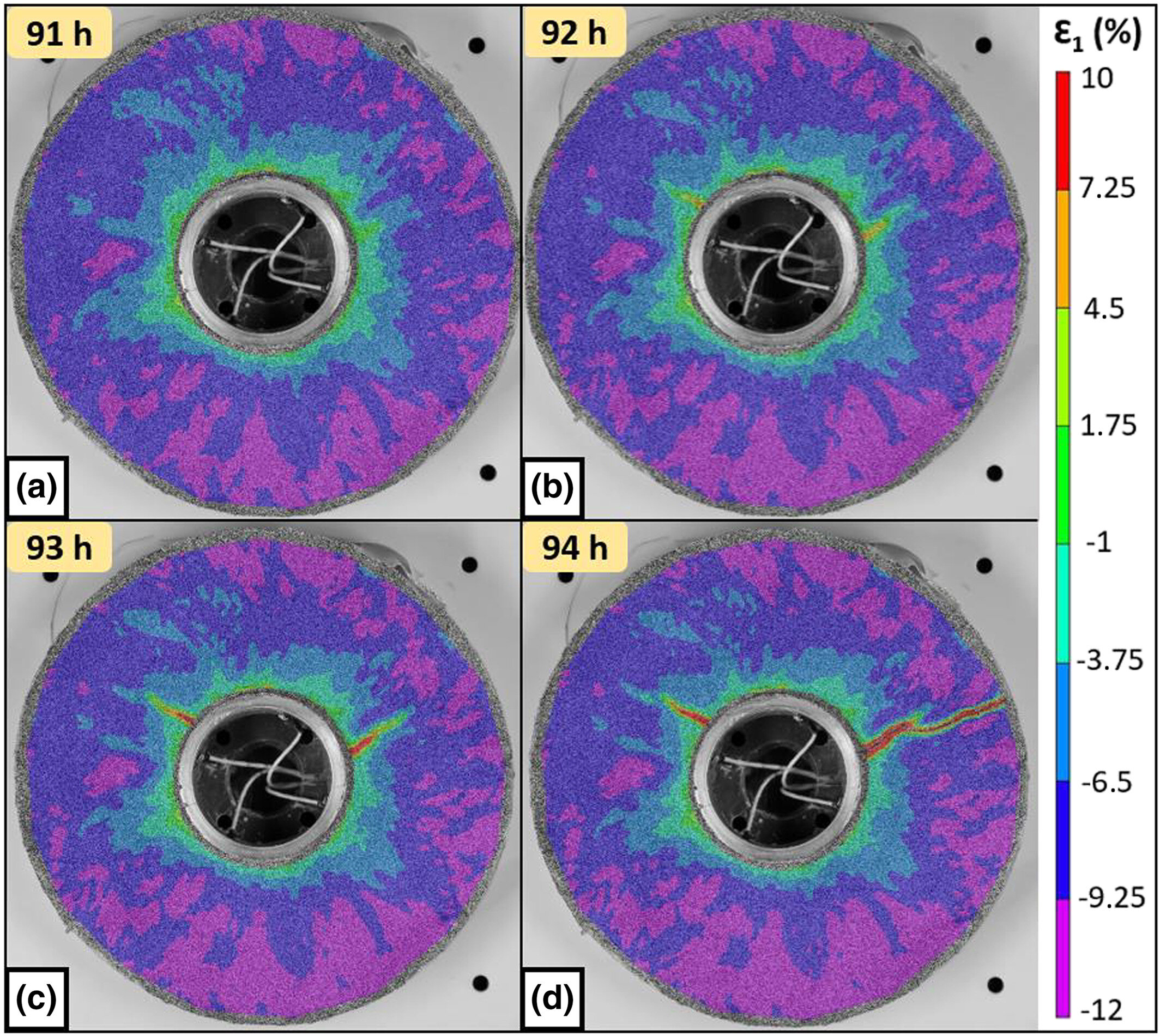

Measuring 3D Volume of Reinforced Rubber Matrix Composite

A reinforced rubber matrix composite is mounted between two grips, and a set of reference images are acquired from a CT scanner at know increments. Each ‘slice’ of data is then analyzed to compute a static volume measurement. After the specimen undergoes a tensile load, images are acquired again by the CT scanner at the same locations.

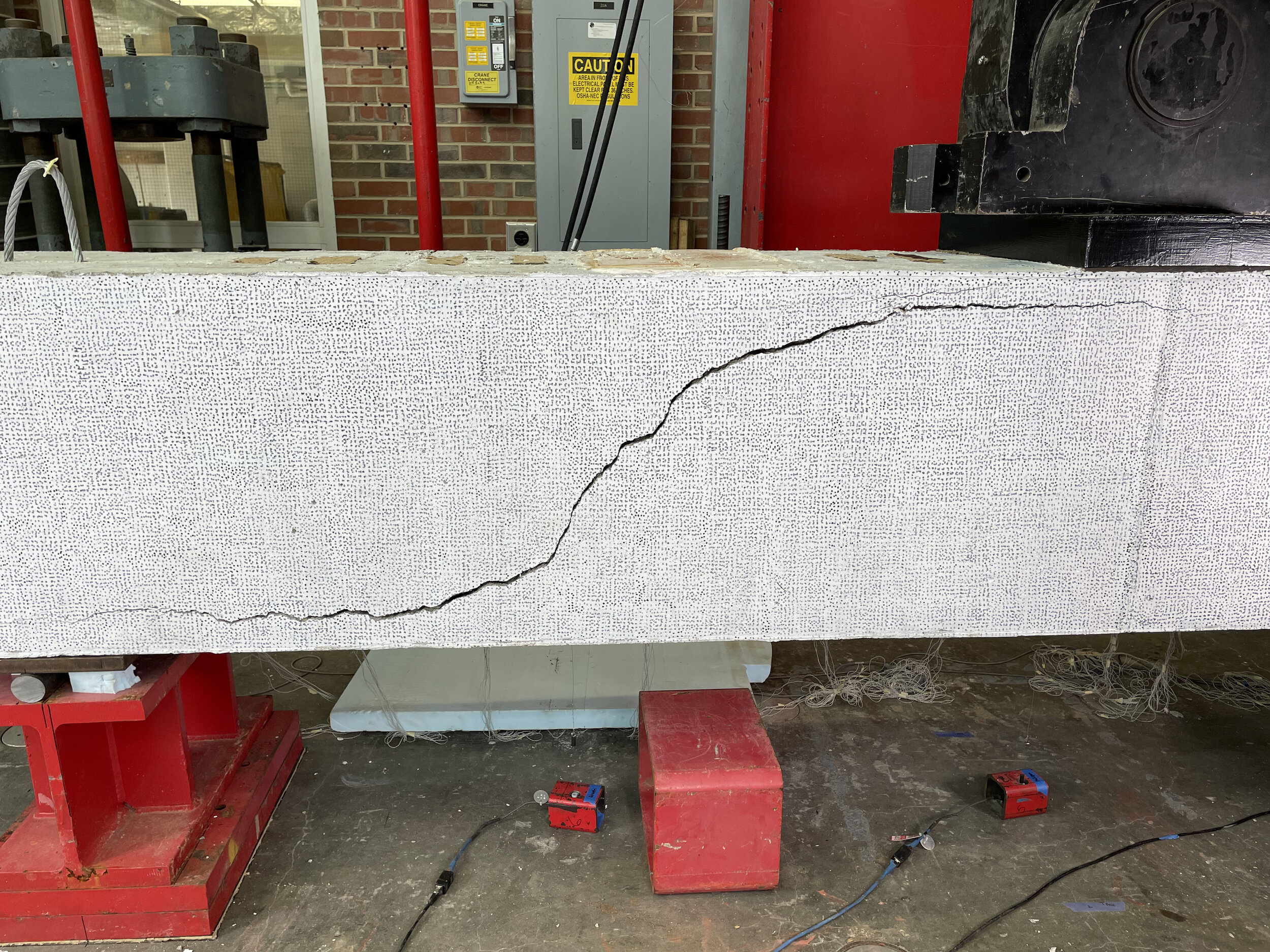

Behavior of Metals During High-Speed Dynamic Compression

Studying the behavior of metals during a high-speed dynamic compression event has always been challenging due to the complex test set up and fast data capture rates required. Currently, very little literature is available regarding deformation behavior at strain rates of 10 to 500s-1. Utilizing high-speed cameras, the VIC-3D HS system can be used to quantify the surface displacements and strains in three dimensions over the entire field with great precision. Digital image correlation (DIC) has gained widespread popularity over recent years in such high-speed applications due to its high accuracy, flexibility and ease of use.

Printed Circuit Board (PCB) Measurement from Thermal Loading

Printed circuit boards (PCBs) have two primary functions: to provide electrical connections between terminals on the board, and to affix electronic components such as resistors, capacitors, and microchips via soldering. PCBs are used in many devices around the world on a day-to-day basis. Their small and lightweight design allows them to be found in nearly every electronic device, such as smart watches, phones & computers, and even digital cameras.